Process And Control Instruments

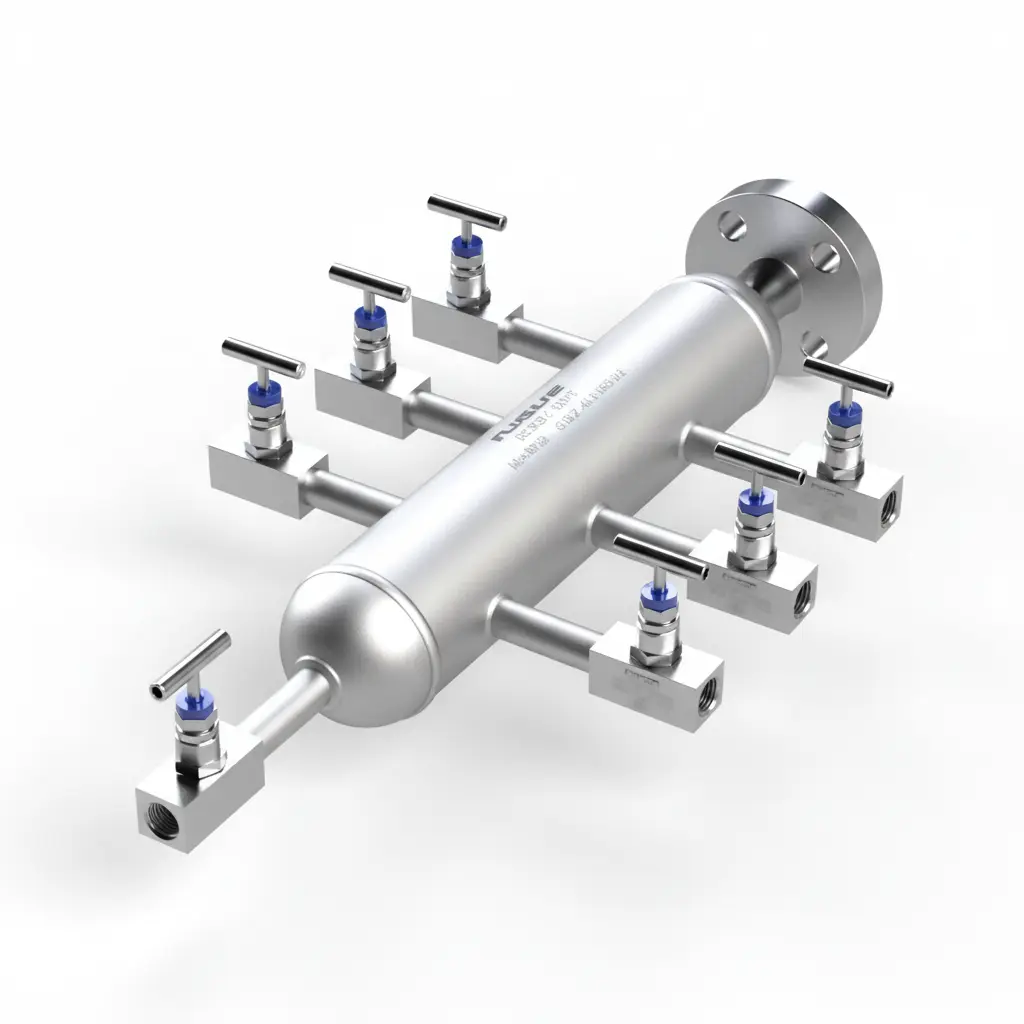

Air Header

Serves as a centralized distribution manifold for compressed air or gas; channels flow evenly through multiple outlet ports, each equipped with isolation valves for precise and independent control.

Back Pressure Reducing Valve

Operates on a spring-loaded diaphragm mechanism; automatically regulates downstream pressure by lifting the diaphragm when upstream pressure exceeds the set limit, ensuring stable flow control.

Basket Type Strianer

Filters fluid through a perforated or mesh basket, effectively trapping suspended particles; allows only clean fluid to pass, protecting downstream equipment from damage or blockage.

Conical Type Strainer

Functions as a static filtration unit installed between pipeline flanges; efficiently removes debris and particulates, ensuring smooth flow and protection of downstream equipment.

Duplex Type Strainer

Divides the process flow between two filtration chambers; allows continuous operation during cleaning or maintenance while effectively trapping solids for clean fluid output.

Full View Sight Glass

Features a cylindrical glass body secured between flanged or threaded ends; provides 360° visual monitoring of fluid flow, clarity, and color in process lines.

Sight Flow Indicator (Double Window )

Operates on a visual inspection principle; features dual glass windows made of toughened or borosilicate material for clear observation of fluid flow within process lines.

Pressure Regulating Valve

Balances downstream pressure through a spring-loaded diaphragm mechanism; automatically adjusts valve opening to maintain stable pressure and ensure safe, efficient operation.

T - Type Strainer

Filters process fluid through a perforated or mesh screen element; efficiently traps suspended solids while allowing clean fluid to pass downstream, ensuring equipment protection.

Y - Type Strainer

When fluid enters the strainer, it passes through a perforated or mesh screen that traps debris and solid particles. The cleaned fluid exits the outlet while the contaminants are collected inside the screen.